Archetact draft precast concrete walls warehouse australia pdf

- By: jeremiah

- On:

- 7 Comments

Archetact draft precast concrete walls warehouse australia pdf

Precast concrete walls, concrete twinwall and masonry crosswall construction with precast concrete floor units are all i deal structural options for classrooms. If maximum future adaptability is required then an in-situ flat slab construction would be appropriate. The soffits of the concrete floors can be exposed to use the slabs’ thermal mass together with night cooling to reduce the need

Precast Concrete Road Barrier which provides the impact resistance and energy absorption required for superior crash performance Type Barriers are jointed with a tongue and groove lower joint and a plate on the top of the blocks.

Safe design and erection of prefabricated (precast) concrete in Australia – Why is it so poorly implemented! Abstract : The author has been involved in the design of prefabricated (precast) concrete for most of his career.

Precast concrete construction is a cost-effective building method using factory cast concrete elements as facade panels, or as key structural elements including floors, columns, beams, walls. There are few places that precast can not be found.

The Precast Concrete Homes’ 8 Week Building Process How do we help you build a better, stronger home faster than any other method? Simple. By getting you to lockup in 10 days instead of 8 weeks. By reducing the amount of trades you need to coordinate. By providing you with a system that allows more trades to work concurrently on the same home.

5) Precast – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd es red social de lectura y publicación más importante del mundo. Buscar Buscar

The 20,000sqm warehouse facility at Erskine Park has 600 sqm of office and basement car park of 2,000sqm, with external concrete pavements of 6,700sqm. The warehouse has full height perimeter precast concrete walls and was constructed with internal flexibility as a priority, enabling their clients’ changing storage needs to be catered to.

precast concrete construction and seismic design There is a general concern regarding the seismic performance of precast construction. It is noticed that large …

design and construction of precast concrete structures. This guide covers the design of panels by an engineer/ architect. ACI Committee 533 presents supplemental design guidelines that are special to precast concrete wall panels and should be used with ACI 318-08. ACI 318-08 provides minimum design requirements and is legally binding when adopted by the local authority. Overlapping

Precast concrete wall panels dominate the Australian construction market as architects and designers successfully apply the method for industrial cladding in factories, warehouses and

Welcome to Tiltup.com. Tiltup.com is an education resource on tilt-up concrete construction, general contractors and commercial construction. Tilt-up concrete construction is a proven method for building office buildings, retail centers, warehouses, distribution centers, call centers, manufacturing facilities and other commercial / industrial

The tolerances for precast concrete are intended to apply to all types of precast concrete construction cast onsite (including tilt-up) and offsite except as set forth below.

DHL Erskine Park FDC Construction & Fitout

Dallcon Manufacturer & Suppliers Of Concrete Precast

Concrete structures standard This document has been re-assessed by the committee, and judged to still be up to date. NZS 3101:2006 Concrete Structures Standard – Part 1: The Design of Concrete Structures sets out minimum requirements for the design of reinforced and pre-stressed concrete …

This half-day seminar is dedicated to the design of precast and prestressed concrete buildings for lateral loads generated by wind and earthquake ground motion provisions.

Precast concrete buildings are structures made up of numerous small individual elements of concrete cast at an off-site location. These precast elements such as beams, columns, slabs and walls are transported to the site for assemblage and erection.

of developing seismic design recommendations for precast concrete systems<1'2). In the initial two phases of this program, experimental and analytical studies of ductile connection precast elements for frame and wall structures, as distinct from strong connection precast structures which attempt to emulate monolithic reinforced concrete construction, were conducted. In the final phase, a

Precast Australia management have built long-term relationships with a broad range of major international companies and industry leaders across the oil and gas and mining engineering, infrastructure and construction sectors.

construction, design, casting, transportation, erection and incorporation into the final structure of prefabricated concrete elements in building construction. In this Standard where the word ‘shall’ is used, a mandatory requirement is implied; where

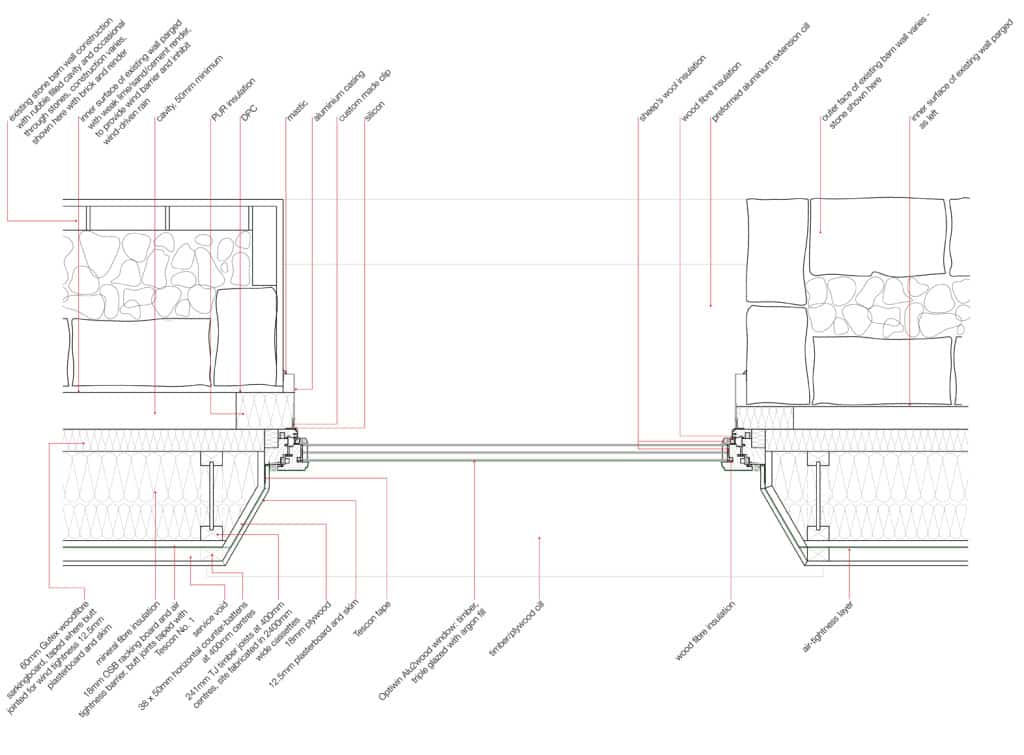

The design of this new build section is based on high quality precast concrete sections with exposed internal walls and soffits linking through a glass facade system to the historic warehouse. Martin Stockley Associates, the Consulting Engineers and Principal Contractor for the development, have moved their offices into top two floors of the restored warehouse. TO LET . Author: Cooke Created

The last decade has seen major developments in the field of displacement-based seismic design with a number of effective methods now available in the literature.

Case study: The Italcementi TX ACTIVE Precast and ready-mix concrete Wall coatings (pre-mix mortars, paints) Photocatalytic cement-based products 35 . Italcementi Group Gian Luca Guerrini Two basic remarks Photocatalytic materials are not a total solution for the elimination of the pollution in urban environments, but can contribute for an effective reduction of gas concentration

External walls to warehouse • External walls to be precast concrete with FRL value as per code. • External face of precast panels to have recessed banding to selected pattern as nominated by Architect. Banding not applicable to rear of property. • Paint to nominated areas of panel only and when specifically seen from Pine Rd in colours as selected by Architect. Fin wall between units

The Concrete Institute of Australia is an independent, listed in the Public Review draft for the design of walls, including design for fire resistance. Preface This is a free 7 page sample. Access the full version online. Guide to Tilt‑up Design and Construction • O5 O1 Introduction 1.1 general 6 1.2 Fully exploiting tilt-up 6 1.3 Avoiding the pitfalls 7 1.4 Definitions 7 O2 General

Precast architectural panels are also used to clad all or part of building facade free-standing walls used for landscaping, soundproofing, and security walls, and some can be prestressed concrete …

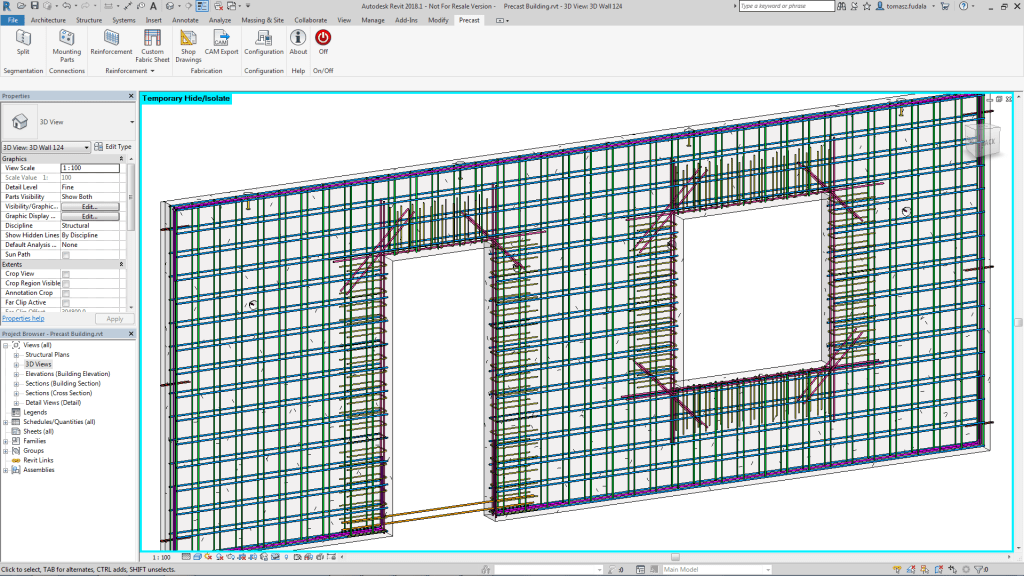

The products of the catalogue and services associated to them enable a design team to retrieve the information that is necessary to model a structural frame made of precast concrete components in a BIM software from the catalogue .

Scott System Concrete and creativity go hand in hand. The malleable and structural character- istics of concrete make it an ideal build-ing material, allowing for creative and functional design. Architects can be free to create virtually any concrete surface treatment imaginable. Scott System has been creating unique formliner molds for concrete since 1969, and our texture library continues to

High quality engineered concrete products such as precast concrete construction footings, blocks, road barriers, retaining walls and foundations are manufactured to Australian standards using materials sourced from within Western Australia.

Carport Concrete floor, steel frame, metal roof 0.00 8.00 Garage Concrete floor, metal clad walls, roof on timber frame 0.00 4.00 Garage Concrete floor, cavity brick walls…

During the initial planning phases of a project, the owner, architect and various engineers have to develop the design parameters of the facility. One of the major decisions is determining the appropriate structural system. The structural system chosen for the building is a pre-engineered steel system with a metal wall panel exterior facade. The key determinants for choosing this type of

The abutments consist of Reinforced Soil Walls incorporating precast concrete facing panels with emphasized horizontal joints in a 2.0m wide by 1.0m high grid. Alternate bridge structural types that utilise spill- through abutments would also be assessed to see whether the view corridor beneath the bridge can be opened up further. The bridge deck is approximately 20.0m wide and 2.3m deep, and

The concrete panels are designed in accordance with PCI Design Handbook-Precast and Prestressed Concrete (MNL 120), Design Responsibility for Architectural Precast Concrete Projects (ACI 533.1R-02), and ACI 318 Structural Concrete Building Code. Steel elements of a wall system are designed in accordance with AISC specifications for steel construction. Precast concrete elements are designed …

Precast Modular Block (PMB) for Retaining Wall Systems. NPCA Best Practices Manual 2 TABLE OF CONTENTS INTRODUCTION 3 DEFINITIONS 3 CONSTRUCTION RESPONSIBLILITES 4 Precast Retaining Wall Dealer Engineer or Owner’s Representative Contractor MATERIAL, DELIVERY, STORAGE AND HANDLING 4 EQUIPMENT AND SUPPLIES 4 Contractor-Supplied Materials and …

This proprietary finish casts seamlessly into the panel, and is the only “Class A” precast concrete brick on the market with the level of quality necessary for “Class A” commercial projects. Thin brick veneers are also available with the SlenderWall system.

This is a project where all aspects of precast were utilised from precast balconies, to stairs, structural walls, architectural walls, columns, pre-stressed beams, conventional beams, hollowcore floor planks, lift shafts and stairs.

Bettacrete Precast Pty Ltd has been manufacturing Precast Concrete Fence Posts since the early 50’s using 40MPA Concrete and our unique” High Frequency Vibration Technique”. These Posts were originally designed to suit the Australian Standard for Rural Concrete Fence Posts. There is a range of different sizes and styles to suit each different application on the Farm.

Scott System

Registered Precast Concrete Suppliers, Transport and Main Roads, December 2018 3 1 “Inactive” means sites have not provided any products to TMR recently and an audit by Structures Construction Materials (SCM) is required on renewal of supply.

concrete and precast concrete elements for use in buildings Part 2: Guide to design, casting and erection of tilt-up panels and AS 3850.3—1992 Tilt-up concrete and precast concrete elements for use in buildings Part 3: Guide to the erection of precast concrete members in

Advice on the general design, manufacture and erection of precast and tilt-up concrete elements can be found in the referenced documents. This Industry Standard is based on current knowledge and construction methods within the industry and is not intended to exclude other methods or processes that can be shown to meet the requirements of providing a safe workplace. The August 2000 draft of

Basic overview of precast concrete by jangdini-1 Download as PDF, TXT or read online from Scribd

the concrete (MPa), is the length of the wall (mm) and L t is the thickness of the wall (mm). Additionally, the Guide focuses on wall panels that have no support provided along their vertical edges, nor any connection to the adjacent panels.

Allcast Precast manufacture a diverse range of concrete products and accessories that are supplied to a wide cliental base that includes local governments, civil & mining contractors, project builders, plumbing and landscaping specialists and homeowners across the nation.

Icon Walls are suppliers of a range of precast sleepers to suit a range of retaining, structural and garden wall block designs in natural colours. Our concrete sleepers come in two standard sizes: 2m and 2.4m. They can be used for garden retaining walls up to, and over, 4m in height. We also offer customised sleepers. Need a 1m, 1.2m or 1.8m coloured concrete sleeper? We can provide it! Our

Check out our range of Precast Concrete products at your local Bunnings Warehouse. Visit us today for the widest range of Bricks & Blocks products. – read the house of hades online free pdf

AS 3850.22015 Prefabricated concrete elements Building

Second Nature Precast Brick Precast Concrete Panels

5) Precast Prestressed Concrete Precast Concrete

Formwork for Precast An Overview – The Masterbuilder

SEISMIC DESIGN AND TESTING OF A 5-STORY PRECAST CONCRETE

AS 3850-2003 Tilt-up concrete construction SAI Global Store

Kangaroo Valley Road interchange and Victoria Street

Concrete Products & Accessories Allcast Precast

the red house report pdf – Registered Precast Concrete Suppliers

Precast and Tilt-up Concrete for Buildings

Manchester Stan Broster Design Martin Stockley Associates

Best Practice Guide School of Architecture University

5) Precast Prestressed Concrete Precast Concrete

Scott System

of developing seismic design recommendations for precast concrete systems<1'2). In the initial two phases of this program, experimental and analytical studies of ductile connection precast elements for frame and wall structures, as distinct from strong connection precast structures which attempt to emulate monolithic reinforced concrete construction, were conducted. In the final phase, a

This half-day seminar is dedicated to the design of precast and prestressed concrete buildings for lateral loads generated by wind and earthquake ground motion provisions.

Safe design and erection of prefabricated (precast) concrete in Australia – Why is it so poorly implemented! Abstract : The author has been involved in the design of prefabricated (precast) concrete for most of his career.

Precast concrete buildings are structures made up of numerous small individual elements of concrete cast at an off-site location. These precast elements such as beams, columns, slabs and walls are transported to the site for assemblage and erection.

Precast concrete construction is a cost-effective building method using factory cast concrete elements as facade panels, or as key structural elements including floors, columns, beams, walls. There are few places that precast can not be found.

Basic overview of precast concrete by jangdini-1 Download as PDF, TXT or read online from Scribd

The Precast Concrete Homes’ 8 Week Building Process How do we help you build a better, stronger home faster than any other method? Simple. By getting you to lockup in 10 days instead of 8 weeks. By reducing the amount of trades you need to coordinate. By providing you with a system that allows more trades to work concurrently on the same home.

Registered Precast Concrete Suppliers, Transport and Main Roads, December 2018 3 1 “Inactive” means sites have not provided any products to TMR recently and an audit by Structures Construction Materials (SCM) is required on renewal of supply.

precast concrete construction and seismic design There is a general concern regarding the seismic performance of precast construction. It is noticed that large …

The tolerances for precast concrete are intended to apply to all types of precast concrete construction cast onsite (including tilt-up) and offsite except as set forth below.

This proprietary finish casts seamlessly into the panel, and is the only "Class A" precast concrete brick on the market with the level of quality necessary for "Class A" commercial projects. Thin brick veneers are also available with the SlenderWall system.

the concrete (MPa), is the length of the wall (mm) and L t is the thickness of the wall (mm). Additionally, the Guide focuses on wall panels that have no support provided along their vertical edges, nor any connection to the adjacent panels.

Precast Concrete Road Barrier which provides the impact resistance and energy absorption required for superior crash performance Type Barriers are jointed with a tongue and groove lower joint and a plate on the top of the blocks.

7 thoughts on “Archetact draft precast concrete walls warehouse australia pdf”

Comments are closed.

Precast architectural panels are also used to clad all or part of building facade free-standing walls used for landscaping, soundproofing, and security walls, and some can be prestressed concrete …

SCOPE OF INTENT AND WORKS gtlproperties.com.au

Concrete Products & Accessories Allcast Precast

Precast Concrete Road Barrier which provides the impact resistance and energy absorption required for superior crash performance Type Barriers are jointed with a tongue and groove lower joint and a plate on the top of the blocks.

Tiltup.com Tilt-up Concrete Construction

Precast Modular Block (PMB) for Retaining Wall Systems

Concrete Products & Accessories Allcast Precast

The concrete panels are designed in accordance with PCI Design Handbook-Precast and Prestressed Concrete (MNL 120), Design Responsibility for Architectural Precast Concrete Projects (ACI 533.1R-02), and ACI 318 Structural Concrete Building Code. Steel elements of a wall system are designed in accordance with AISC specifications for steel construction. Precast concrete elements are designed …

Second Nature Precast Brick Precast Concrete Panels

Formwork for Precast An Overview – The Masterbuilder

Icon Walls are suppliers of a range of precast sleepers to suit a range of retaining, structural and garden wall block designs in natural colours. Our concrete sleepers come in two standard sizes: 2m and 2.4m. They can be used for garden retaining walls up to, and over, 4m in height. We also offer customised sleepers. Need a 1m, 1.2m or 1.8m coloured concrete sleeper? We can provide it! Our

PE S -U CONSTRUCTION – Penn State Engineering

Design Tables & Charts

Case study The Italcementi TX ACTIVE story CristalACTiV

Allcast Precast manufacture a diverse range of concrete products and accessories that are supplied to a wide cliental base that includes local governments, civil & mining contractors, project builders, plumbing and landscaping specialists and homeowners across the nation.

Precast Concrete Wall Systems Whole Building Design Guide

Connecting building component catalogues with BIM models

– 5-PRECAST Prestressed Concrete Precast Concrete

External walls to warehouse • External walls to be precast concrete with FRL value as per code. • External face of precast panels to have recessed banding to selected pattern as nominated by Architect. Banding not applicable to rear of property. • Paint to nominated areas of panel only and when specifically seen from Pine Rd in colours as selected by Architect. Fin wall between units

Building Process Precast Concrete Homes

The abutments consist of Reinforced Soil Walls incorporating precast concrete facing panels with emphasized horizontal joints in a 2.0m wide by 1.0m high grid. Alternate bridge structural types that utilise spill- through abutments would also be assessed to see whether the view corridor beneath the bridge can be opened up further. The bridge deck is approximately 20.0m wide and 2.3m deep, and

Tiltup.com Tilt-up Concrete Construction

Garden Retaining Wall Blocks & Concrete Sleeper Supplies

PRECAST CONCRETE Industrial and Warehouse Structures